A Canadian Company

A Canadian Company

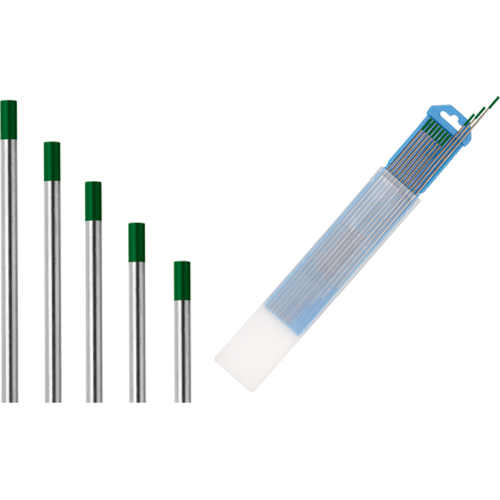

| Model | NP541 |

| Manufacturer Model No | T187G |

| Description | TIG welding electrodes usually contain small quantities of metallic oxides which can offer the following benefits: -Facilitate arc starting -Increase arc stability -Improve current carrying capacity of the electrode -Reduce the risk of weld contamination -Increase electrode life |

| Specification | Diameter: 1/8" |