| Description | TIG welding electrodes usually contain small quantities of metallic oxides which can offer the following benefits: -Facilitate arc starting -Increase arc stability -Improve current carrying capacity of the electrode -Reduce the risk of weld contamination -Increase electrode life

Oxides used are primarily zirconium, thorium, lanthanum or cerium

Additions are 1% - 4%, improve arc initiation, especially when direct current (DC) welding is employed

Thorium oxide (thoria), effective in terms of long life and thermal efficiency

Zirconium oxide (zirconia) has been commonly used for alternating (AC) TIG welding, welding aluminum

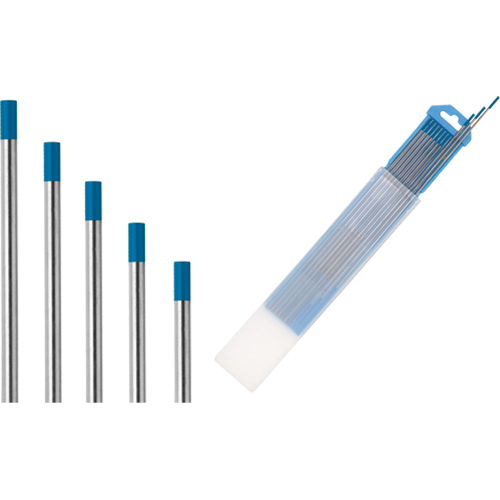

Electrode length: 7"

Each package contains 10 electrodes; 2% Lanthanated:

Non-radioactive

Best general purpose electrode at medium to highter amperage for both A/C or D/C using inverter or transformer based constant current power sources

Good for low-alloyed steels, non corroding steels, aluminum alloys, magnesium alloys, titanium alloys, nickel alloys, and copper alloys

Good arc starts and stability, low erosion rate, medium to high current range |